[10000ダウンロード済み√] 3/8-16 unc-2b pitch diameter 333913-What is 3/8-16 unc

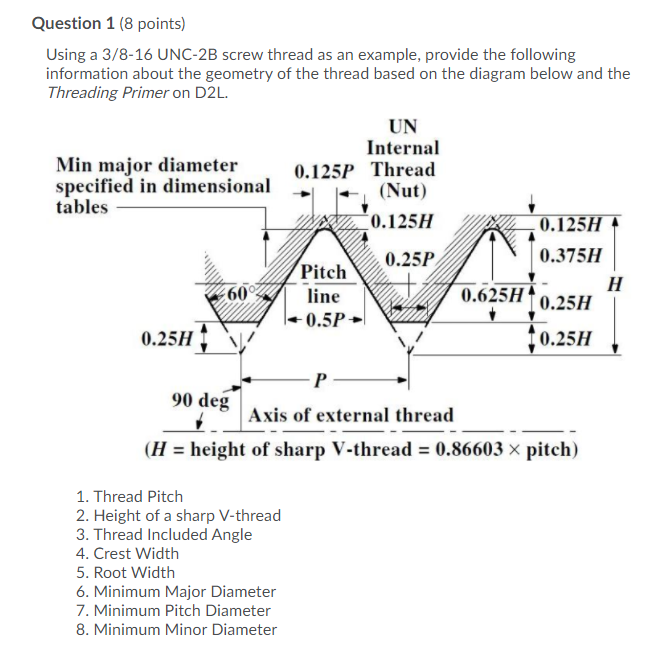

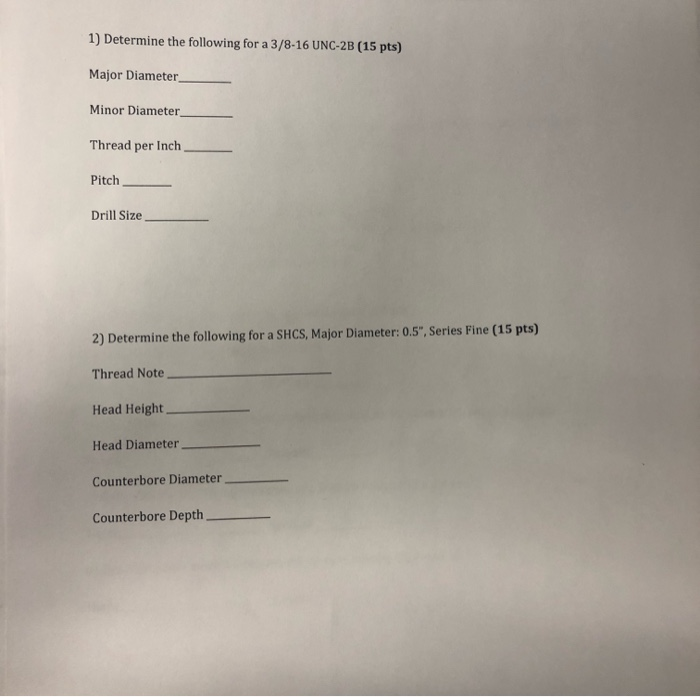

Fracs Size TPI Basic Hi Hi 3A Go 3A Lo 2A Go 2A Lo Fracs Size TPI Basic Hi Hi 3A Go 3A Lo 2A Go 2A Lo 54 Thread Check Product Catalog TollFree Phone Fax 034 TCI_Catalog_1008indd 54 10/21/08 PM3/816 UNC 2B (21) The "2B" is a tolerance class The standards for a thread series include specifications of tolerances Most specify several different classes, because for some uses a close fit is essential, while achieving it for other uses would be a waste of moneyTap size NF/NC UNF/UNC Threads per inch Basic major dia (inches) Basic effective dia (inches) Basic minor dia of ext threads (inches) Basic minor dia of int threads (inches) Drill size 080 UNF 80 0600 0519 0447 0465 3/64 164 UNC 64 0730 0629 0538 0561 #54 256 UNC 56 0860 0744 0641 0667 #50 264 UNF 64 0860 0759 0668 0691 #50

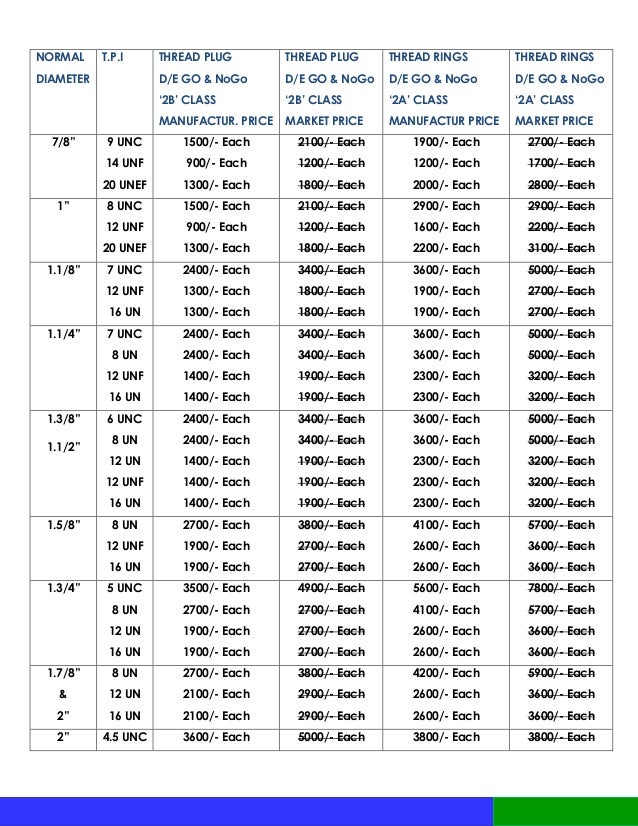

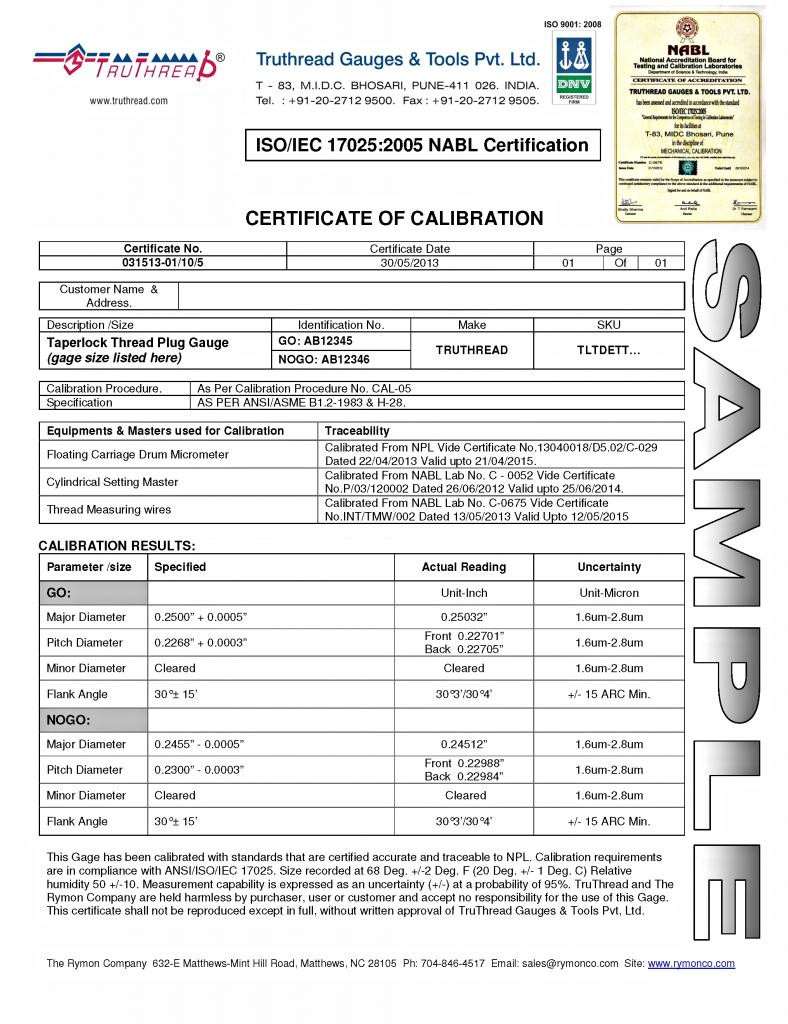

Industrial Metrology Go And No Go Thread Plug Gauges Thread Gages

What is 3/8-16 unc

What is 3/8-16 unc-Length of Insert (in Diameter) Nominal Length Diameter;ANSI/ ASME INTERNAL Screw Thread Size Chart All units are in inches Unified Screw Threads per ANSI/ASME B1119 (R01), R01) Nomenclature, are used Acceptability criteria are described in ANSI/ASME B13M1992 (R01)

3 8 16 Unc 2b Thread Plug Gage Go Nogo 375 16 Tpi Titan Gage Ebay

Threaded Plug Gauge Assembly, Thread Type UNC, Thread Size 3/8"16, Thread Class 2B Item # 6DHL7;Tap size NF/NC UNF/UNC Threads per inch Basic major dia (inches) Basic effective dia (inches) Basic minor dia of ext threads (inches) Basic minor dia of int threads (inches)Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #1 64 UNC 0073 1854 150 64 0397 #2 56 UNC 0086 2184 1

Unified Screw Thread Chart, UNC, UNF, UNEF, Major Diameter, Minor Diameter, Pitch, External Thread, Internal Thread, Size from #0 to 25Screw Thread Designations, Minor Diameter, Major Diameter, Pitch Diameter;Nominal size unified pitch diameter class 2a class 3a x tol go = – no go = go not go go not go #080 unf #164 unc

Cast Iron Flanges Stud Reference Chart The number, diameter and length of studs for cast iron flanges class 125 and 250;Gage a ssembly manufacturers of precision gages standard pitch diameter chart /lspjhs *vps 7s\n hnlz nominal 0a, go pitch diameters x tol go = no go =– ) 56;ANSI/ ASME EXTERNAL Screw Thread Size Chart All units are in inches Unified Screw Threads per ANSI/ASME B1119 (R01), R01) Nomenclature, are used Acceptability criteria are described in ANSI/ASME B13M1992 (R01)

Test Measure Inspect 3 8 16 Unc Class 2b Sti Taperlock Screw Thread Insert Plug Gage Set Industrial Scientific Rdtech Co Rw

Type Of Threads How To Identify Threads

THREAD PITCH CHART (UNC / UNF / UNEF / UN) Thread pitch chart for UNC, UNF, UNEF and UN up to 2 inch according to ASME B11 Thread pitch chart Threads / in Nominal Size, in Series With Graded Pitches Series with Constant Pitches Nominal Size, in Basic Major Diameter UNC UNF UNEF 4UN 6UN 8UN 12UN 16UN UN 28UN 32UNUNC UNF Diameter Index DiameterACT ALWAYS PRECISE Standard Pitch Diameter Chart 16 Plug Thread Gages NOMINAL SIZE UNIFIED PITCH DIAMETERS CL 2B CL 3B #0 80 UNF 0519 0542 0536 0002 0002 0°30'

Www Threadcheck Com Content Pdf Thread Check Catalog 16 Pdf

1 1 8 16 Un 2b Thread Plug Gage 1 125 Go No Go Pd S 1 0844 1 0909 Quality Ebay

Nut Size 10 019 #9 24 #25 32 #21 #23,#22 Gage and Fractional Sizes Clearance Drill Tap Drill for UNC UNF tpi Tap Drill for UNF #7 28 #3 32 UNC, UNF, UNEF, UNS screw thread gauges to one inch in diameter These series (and the UNR, UNJ and fixedpitch series) are the inchbased thread series currently used in the United States, and1 15 2 25 3 Min Max 1 15 2 25 3;Pitch Diameter Minor Diameter Male Thread Minor Diameter Female Thread;

Unc Thread Ansi Asme B1 1

Reiff Nestor 3 8 16 Unc 3 Flute H3 Bright Finish High Speed Steel Spiral Point Extension Tap Msc Industrial Supply

2)The UNF threads have smaller pitch, there are more teeth are screwed in the same thread length, it can reduce fluid leakage, so it is used in the applications where sealing is needed 3)The UNC thread has less teeth of the same length, larger crosssection size of each tooth, and more suitable for bearing larger tensile force and impact forceMfr Model # Pitch Diameter Go Member in;NoGo Pitch Diameter " Material 01 Tool Steel 6062 RC;

Http Homepages Cae Wisc Edu Me231 Online Notes Dimensoning Fastener Handout Pdf

3 8 16 Unc Class 2b Sti Taperlock Screw Thread Insert Plug Gage Set Amazon Com Industrial Scientific

It will follow an "x" after the diameter number Specifying the pitch is important for distinguishing between coarse and fine screws Coarse screws have a larger pitch than similarlysized fine screws A M12 x 175 x 85 screw, for instance, has threads every 175 mm (0069 in) The second number, 175, indicates the pitchDiameter Pitch TPI Thread Fit Class Major Diameter Pitch Diameter Minor Diameter Stress Area Max Min Max Min Max Min in² No 1 64 2A No 2 56 2A No 3 48 2A 009 005ANSI/ ASME INTERNAL Screw Thread Size Chart All units are in inches Unified Screw Threads per ANSI/ASME B1119 (R01), R01) Nomenclature, are used Acceptability criteria are described in ANSI/ASME B13M1992 (R01)

Www Redlinetools Com Customer Docs Skudocs Tap General Purpose Speeds P405 416 Pdf

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Thread Size Nominal Length 1 Free Outer Diameter Number of Free Coils 2;Relation Of Tap Pitch Diameter To Basic Pitch Diameter American tap manufacturers use a series of tap pitch diameter limits These limits feature a 0005" tolerance in tap sizes #0 through 1 inch, and a 001 inch or greater tolerance in tap sizes above 1 inch through 11/2 inch diameter, inclusiveWire Diameters Diameter of the wires used to measure the dimension close to the pitch diameter the external screw thread Tolerances Allowance Fundamental deviation of the basic size, applies only to 1A and 2A external classes Major/Pitch/Minor diameters The difference between the maximum and minimum diameters

Solved Question 1 8 Points Using A 3 8 16 Unc 2b Screw Chegg Com

Tap Tolerance Unc Uncf Next Generation Tooling

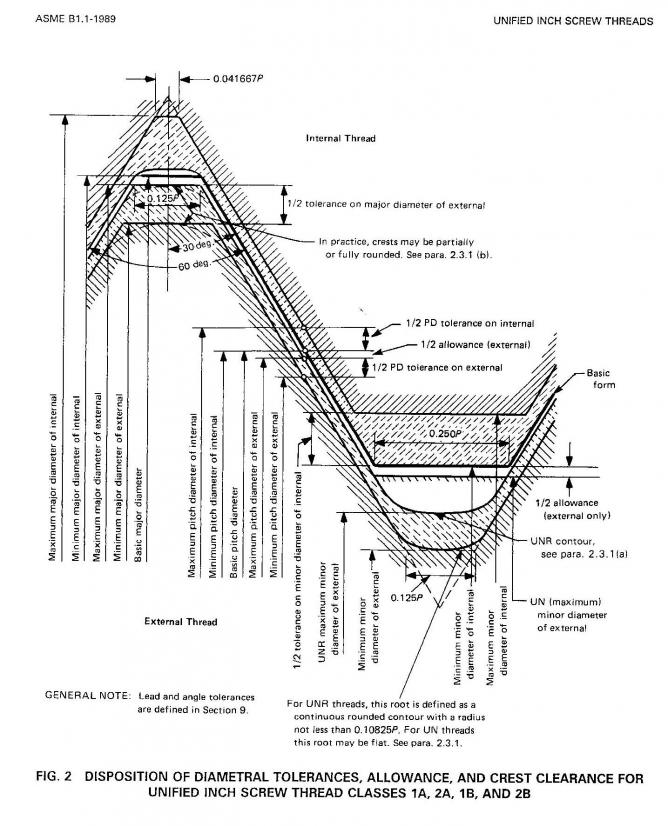

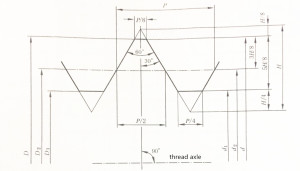

Max Major Min Major UNR Minor Dia TPI Pitch P/4 P/8 Max Minor Min Minor Major Dia(Min) inch inch inch inch inch inch inch inch inch inch Ext 5/ 1618 UNC 18 0013 1A 029 Int 18 0013 1B 0265 0252 Ext 5/ 1618 UNC 18 0013 2A 0298The basic pitch diameter is the nominal (mean) pitch diameter of the product assembly, internal and external thread It is the base value for the application of the thread class and allowance Figure 1 illustrates the thread class, allowance and the basic pitch diameter for both unified inch screw threads and M Series metric screw threads andThread series cover designations of diameter/pitch combinations that are measured by the number of threads per inch (TPI) applied to a single diameter Coarse Thread Series (UNC/UNRC) is the most common designation for general application bolts and nuts Coarse thread is beneficial, because they are less likely to cross thread, more tolerant in

Measuring Gauge Price List 16

Www Swansongage Com Customer Content Www Cms Files Precision Thread Plain Gage Pdf

Product Compare (0) Sort By Show Vermont Gage 3/816 UNC 2B TAPERLOCK Thread Plug Gage, Go Member Only *actual product may differ Vermont Gage 3/816 UNC 2B TAPERLOCK Thread Plug Gage, Go/NoGo $7800 $00 Add to Cart Vermont Gage 3/816 UNCRelation Of Tap Pitch Diameter to Basic Pitch Diameter American Tap Manufacturers use a series of tap pitch diameter limits These limits feature a 0005 tolerance in tap sizes #0 Thru 1" and a 001" or greater tolerance in tap sizes above 1" thru 1 1/2" diameter Example 1/4 Relationship between Tap Pitch diameter limits and basic nominalThread Direction Right Hand;

Www Swansongage Com Customer Content Www Cms Files Precision Thread Plain Gage Pdf

3 8 16 Unc Class 2b Taperlock Thread Plug Gage Set Thread Gauges Industrial Scientific

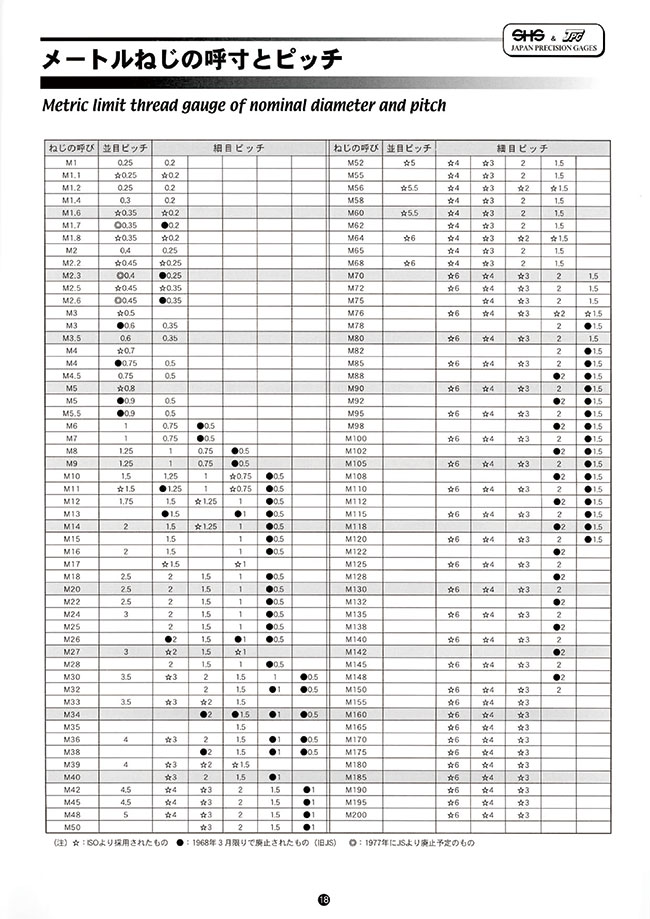

Nominal size & pitch for external thread for internal thread pitch diameter go ring gage 6g tolerance pitch diameter not go ring gage 6g tolerance pitch diameter go plug gage 6h tolerance pitch diameter not go plug gage 6h tolerance mm in (ref) mm in (ref) mm in (ref) mm in (ref) m 16x 035 1354 1291 050 1373 1458EN Pipe threads where pressure tight joints are made on the threads Dimensions Pipe threads where pressure tight joints are made on the threads Part 1 Taper external threads and parallel internal threadsAn H2 tap from 0005" over basic

Un Thread Gauges Un Ring Gage Un Plug Gage Go Nogo Gaugestools

Greenfield Threading Spiral Point Tap 3 8 Quot 16 Plug Unc 3 Flutes Walmart Com Walmart Com

Working Thread Plug, Thread Ring and Thread Setting Plug Gages are manufactured to inspect the Pitch Diameter and the Functional Thread Thread gages are used to ensure the assembly of mating parts Unified Inch standard gages are manufactured per ASME B12 M Series Metric thread gages are manufactured per ASME B116MTaps Pitch Diameter Limit Pitch Diam Limits Maximum Pitch Diam Limits Maximum Pitch Diam Limits Maximum Pitch Diam Limits Maximum All Classes Minimum Basic Pitch Diameter Threads Per Inch Unified Classes of Thread American National ISO Metric Class of Threads Size mm Pitch mm NC UNC NF UNF Rec* Taps Rec* Taps Rec* Taps CLASS 2B ForPitch Diameter NoGo Member in;

Mae Ufl Edu Designlab Online resources Files Fastener Handout Pdf

3 8 16 Left Hand Unc Class 2b Taperlock Thread Plug Gage Set The Rymon Company

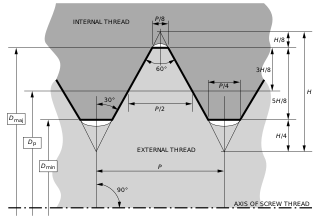

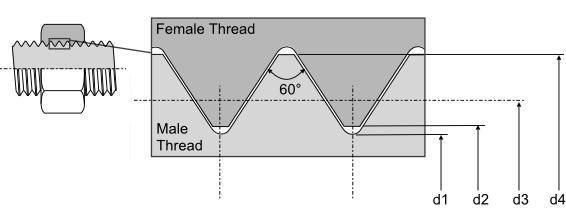

Threads per inch 16 Series UNC;Each thread in the series is characterized by its major diameter D maj and its pitch, PUTS threads consist of a symmetric Vshaped thread In the plane of the thread axis, the flanks of the V have an angle of 60° to each other The outermost 1 ⁄ 8 and the innermost 1 ⁄ 4 of the height H of the Vshape are cut off from the profile The pitch P is the distance between thread peaksThread plug gages nominal size go basic all classes all series unified pitch diameters not go x tolgo =no go=– xleadtol x ±halfangletol cl 2b cl 3b #0 80 unf 0519 0542 0536 0002 0002 0°30' #1 64 unc 0629 0655 0648 0002 0002 0°30' #1 72 unf 0640 0665 0659 0002 0002 0°30' #2 56 unc 0744 077

3 8 16 Unc 2b Thread Plug Gage Go Nogo 375 16 Tpi Titan Gage Ebay

Vermont Gage Go Nogo Standard Thread Gauge Set Class X Asme B1 2 2a Ring 3 8 16 Unc Thread Size 3t Handle Thread Gauges Amazon Com Industrial Scientific

Screw Thread Designations, Minor Diameter, Major Diameter, Pitch Diameter;Are designated by the letter H (high) above basic pitch diameter, or L (low) below basic pitch diameter, and these numbers establish the tolerance range in relation to basic pitch diameter As an example, in sizes 1" and smaller, an H1 tap has a tolerance range of from basic to 0005" over basic;Tap size NF/NC UNF/UNC Threads per inch Basic major dia (inches) Basic effective dia (inches) Basic minor dia of ext threads (inches) Basic minor dia of int threads (inches) Drill size 080 UNF 80 0600 0519 0447 0465 3/64 164 UNC 64 0730 0629 0538 0561 #54 256 UNC 56 0860 0744 0641 0667 #50 264 UNF 64 0860 0759 0668 0691 #50

Industrial Nuts Size Charts American Fastener

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Nominal Thread Size Covered Range 080 UNF to ¼56 UNS Nominal thread sizes from 080 UNF to ¼56 UNS 5/1618 UNC to 9/16 32 UN Nominal thread sizes from 5/1618 UNC to 9/16 32 UNFracs Size TPI Basic Hi Hi 3A Go 3A Lo 2A Go 2A Lo Fracs Size TPI Basic Hi Hi 3A Go 3A Lo 2A Go 2A Lo 54 Thread Check Product Catalog TollFree Phone Fax 034 TCI_Catalog_1008indd 54 10/21/08 PMRelation Of Tap Pitch Diameter To Basic Pitch Diameter American tap manufacturers use a series of tap pitch diameter limits These limits feature a 0005" tolerance in tap sizes #0 through 1 inch, and a 001 inch or greater tolerance in tap sizes above 1 inch through 11/2 inch diameter, inclusive

Pitch Diameter Chart1 Building Materials Cutting Tools

Unified Thread Standard Wikipedia

EN Pipe threads where pressure tight joints are made on the threads Dimensions Pipe threads where pressure tight joints are made on the threads Part 1 Taper external threads and parallel internal threads3 NTS I nternal t hreads C lass 2B ASME B1108 Nominal Size & Threads per Inch Series DesignationCast Iron Flanges Stud Reference Chart The number, diameter and length of studs for cast iron flanges class 125 and 250;

Industrial Metrology Go And No Go Thread Plug Gauges Thread Gages

Www Sigmafasteners Com Catalog Section 5 Pdf

UNC / UNF plug gages GGRLD are designed to inspect the pitch diameter and functional thread for internalthread components All plug gages are available with Certificate of Accuracy documentation Gage dimensions according to ANSI/ASME B12 Short form certificate is supplied at no additional charge Long form certificate is available on request Thread gages are for UNC & UNF 3B class of fitDiameter Minor Diameter Pitch Line Axis of internal thread INTERNAL THREADSCLASS 2B ASME B11 Nominal Size & Threads per Inch Series Designation Allowance Minor Diameter Pitch Diameter Major Diameter Min Max Min Max Tolerance Min 080 UNF 164 UNCUnified Screw Thread Chart, UNC, UNF, UNEF, Major Diameter, Minor Diameter, Pitch, External Thread, Internal Thread, Size from #0 to 25

Solved 1 Determine The Following For A 3 8 16 Unc 2b 15 Chegg Com

3 8 16 Unc Class 2b Sti Taperlock Screw Thread Insert Plug Gage Set Thread Industrial Scientific

Nominal Diameter Major Diameter Inch Major Diameter mm Tapping Drill Size mm TPI Pitch mm #1 64 UNC 0073 1854 150 64 0397 #2 56 UNC 0086 2184 1THREAD PITCH CHART (UNC / UNF / UNEF / UN) Thread pitch chart for UNC, UNF, UNEF and UN up to 2 inch according to ASME B11 Thread pitch chart Threads / in Nominal Size, in Series With Graded Pitches Series with Constant Pitches Nominal Size, in Basic Major Diameter UNC UNF UNEF 4UN 6UN 8UN 12UN 16UN UN 28UN 32UNPitch Diameter NoGo Member in;

Http Www Ring Plug Thread Gages Com Surplus Thread Gages Plug Un W Spl Work Screw Thread Gages Pdf

3 8 16 Stainless Steel Partial Thread Arc Stud Www Studweldingstore Com

Are designated by the letter H (high) above basic pitch diameter, or L (low) below basic pitch diameter, and these numbers establish the tolerance range in relation to basic pitch diameter As an example, in sizes 1" and smaller, an H1 tap has a tolerance range of from basic to 0005" over basic;Mfr Model # Pitch Diameter Go Member in;An H2 tap from 0005" over basic

3 4 10 Unc Gpip2b Limit Thread Plug Gauge Unc Sokuhansha Misumi Indonesia

Vermont Gage 3 8 16 Unc 2b Go And No Go Taperlock Gage Assembly Dimensional Measurement Thread Gauges

Class X Tolerance, includes Long Form CertificateCoarse and Fine Threaded Screw Information All Diameters in Inches;Threaded Plug Gauge Assembly, Thread Type UNC, Thread Size 3/8"16, Thread Class 2B Item # 6DHL7;

Cleveland C Spiral Point Tap 3 8 Quot 16 Plug Unc 3 Flutes Walmart Com Walmart Com

Q Tbn And9gcqpyqvrsmikd6k1emfsvq9jfbe84zphdnljmcudjzvbihn4nvfe Usqp Cau

Screw Thread Designations, Minor Diameter, Major Diameter, Pitch Diameter;Size Threads/Inch Outside Diameter Tap Drill Body Drill;UNC plug gages GGRLD are designed to inspect the pitch diameter and functional thread for internalthread components All plug gages are available with Certificate of Accuracy documentation Gage dimensions according to ANSI/ASME B12 Short form certificate is supplied at no additional charge Long form certificate is available on request Thread gages are for UNC 2B class

Q Tbn And9gctskbgnd3qtri4f I3hday1jbiqpfhtecmixuyo68lffe5qvjzx Usqp Cau

3 8 16 Unc Class 2b Taperlock Thread Plug Gage Set Thread Gauges Industrial Scientific

Thread Direction Right Hand;3 1/2 4 323 3 3/4 4 4 4 376 Note Due to the fact that fastening applications differ greatly, the above information is for guidance only and is correct to the best of our knowledgePlease let us know if you need a special pitch diameter quoted!

Q Tbn And9gctskbgnd3qtri4f I3hday1jbiqpfhtecmixuyo68lffe5qvjzx Usqp Cau

Unified National J Series Vs Unified National

Nut Size 10 019 #9 24 #25 32 #21 #23,#22 Gage and Fractional Sizes Clearance Drill Tap Drill for UNC UNF tpi Tap Drill for UNF #7 28 #3 32 UNC, UNF, UNEF, UNS screw thread gauges to one inch in diameter These series (and the UNR, UNJ and fixedpitch series) are the inchbased thread series currently used in the United States, andClass 2B Taperlock Thread Plug Gage DoubleEnd Set Go Pitch Diameter ";

Thread Pitch Chart

Www Sigmafasteners Com Catalog Section 5 Pdf

Thread Gauges 3b Go Taperlock Gage Vermont Gage 3 8 16 Unc 2b Industrial Scientific

Unified National J Series Vs Unified National

Q Tbn And9gcr9yhxk Wsfmtgbqys Rj3vrtiwmvcxtii Uj4zouclj8mpqajs Usqp Cau

Buy Vermont Gage 5 8 32 Un 2b Go Nogo Taper Lock Plug Set Mega Depot

Cleveland C Spiral Point Tap 3 8 Quot 16 Plug Unc 3 Flutes Walmart Com Walmart Com

Xcan 1pc 5 16 3 8 7 16 1 2 5 8 3 4 Unc Unf Unef Hss Machine Plug Tap Straight Flute Screw Tap Right Hand Thread Tap Drill Tap Die Aliexpress

Thread Data Charts Unc Screw Thread Per Ansi B1 1

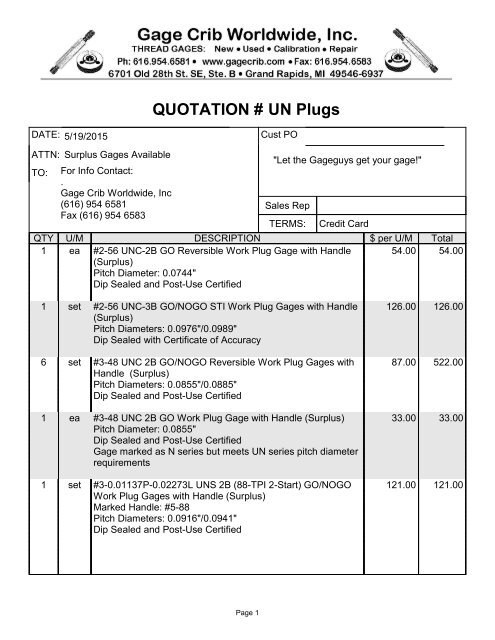

Quotation Un Plugs Ring Plug Thread Gages

Www Redlinetools Com Customer Docs Skudocs Tap General Purpose Speeds P405 416 Pdf

3 8 16 Unc Aluminum Light Duty Weld Nuts At Kiesler Machine Inc

3 8 16 Left Hand Unc Class 2b Taperlock Thread Plug Gage Set The Rymon Company

Mae Ufl Edu Designlab Online resources Files Fastener Handout Pdf

3 8 16 Unc Class 2b Sti Taperlock Screw Thread Insert Plug Gage Set Amazon Com Industrial Scientific

Ansi Internal Screw Threads Size And Tolerances Table Chart Engineers Edge

Www Redlinetools Com Customer Docs Skudocs Tap General Purpose Speeds P405 416 Pdf

3 8 16 X 439 Plain Nylon Threaded Rod Amazon Com Industrial Scientific

Www Threadcheck Com Technical Documents Standard Inch Pitch Diameters Pg54 Pdf

Industrial Nuts Size Charts American Fastener

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Www Stanleyengineeredfastening Com Media Web Sef Resources Docs Heli Coil Hc 00 Rev11 Web Pdf

Pa Schoolwires Net Site Handlers Filedownload Ashx Moduleinstanceid 92 Dataid 325 Filename Fastener Handout Pdf

What Is The Section Size Perimeter On The Coil Tool Autodesk Community Fusion 360

Un Imperial Screw Thread Calculator

3 8 16 Unc 2a Thread Ring Gage No Go Only 375 16 Tpi Master Gage Co Ebay

3 8 16 Unc 2a Thread Ring Gage No Go Only 375 16 Tpi Ebay

Threads

3 8 16 Unc 2b Thread Plug Gage Not Go Only 375 16 Tpi Southern Gage Ebay

3 8 16 Unc Class 2b Sti Taperlock Screw Thread Insert Plug Gage Set Thread Industrial Scientific

Tapping Tip How H Limits Relate To Class Of Fit Part 1 Gws Tool Group

Unified National Coarse Thread Unc Thread Chart Apollo International

3 8 16 Unc Thread Gauge Ring Plug Gage 2a 2b Go Nogo Gaugestools

Vermont Gage 3 8 16 Unc 2b 3b Taperlock Plug Go Gage Kaufman Company Inc

Www Deltafastener Com Pdf Delta Fastener Catalog Pdf

Understanding Thread Names How To Read Thread Designations For National Unified Threads Unc Unf Unef Un Bright Hub Engineering

Unified Thread Standard Wikipedia

Http Www Actequipment Com Gage Pdfs Pitchun Pdf

Threetriangles Weebly Com Uploads 2 5 8 9 Threads And Fasteners Pdf

Greenfield Threading 36 44 Tap Set 3 8 16 Bottoming Plug Taper 4 Flutes Unc Zoro Com

2

Unified Coarse Unc

Unified National Thread Unc And Unf

Vermont Gage Go No Go Plug Gage Assy 3 8 16 Unc 2b Walmart Com Walmart Com

Www Redlinetools Com Customer Docs Skudocs Tap General Purpose Speeds P405 416 Pdf

Un Imperial Screw Thread Calculator

Screw Sizes Screw Sizing Chart Socket Cap Screw Data Asm

Engineer Mechanical Inventor Threads Jeffery J Jensen Wiki

Http Www Nachiamerica Com Content Downloads 17 Catalog Taps Update Small Pdf

3 8 16 Unc 3a Thread Ring Gage No Go Only 375 16 Tpi Greenfield Ebay

3 8 16 Unc Thread Gauge Ring Plug Gage 2a 2b Go Nogo Gaugestools

Greenfield Threading 3 8 16 Unc Carbon Steel Round Adjustable Die Msc Industrial Supply

Www Sigmafasteners Com Catalog Section 5 Pdf

Greenfield Threading 3575 7 81 Spiral Point Tap 3 8 16 Plug 3 Flutes Zoro Com

Cleveland C 24 00 Straight Flute Hand Tap 3 8 16 Bottoming Plug Taper 4 Flutes Zoro Com

Www Osbornproducts Com Pdfs Catalog Pdf

Seco 3 8 16 Unc 2b 3 Flute Tin Finish Powdered Metal Spiral Point Tap Msc Industrial Supply

Imperial Fasteners Fabory

Thread Ring Gage Set 3 8 16 Unc Thread Gauges Amazon Com Industrial Scientific

Www Besly Com Images Beslyspeccat Pdf

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

Osg 1 4 Unc 3 Flute 2b Bottoming Spiral Flute Tap Msc Industrial Supply

Helicoil Tap Chart Helicoil Tapping Chart Helicoil Tap Size Helicoil Tapping Size Helicoil

Everything You Wanted To Know About Taps But Were Afraid To Ask Styles Of Taps Class Of Thread Gh Numbers Basic Point In Thread Measurement Constants For Finding Pitch

コメント

コメントを投稿